Do you have a question?

Please fill out the form and leave your request:

Already implemented in the oil and gas industry

Already implemented in civil construction

Unified web portal for oilfield services

Unified information and analytical system for the preparation, implementation, monitoring, and evaluation of oilfield services.

Download the presentation

Download the presentation

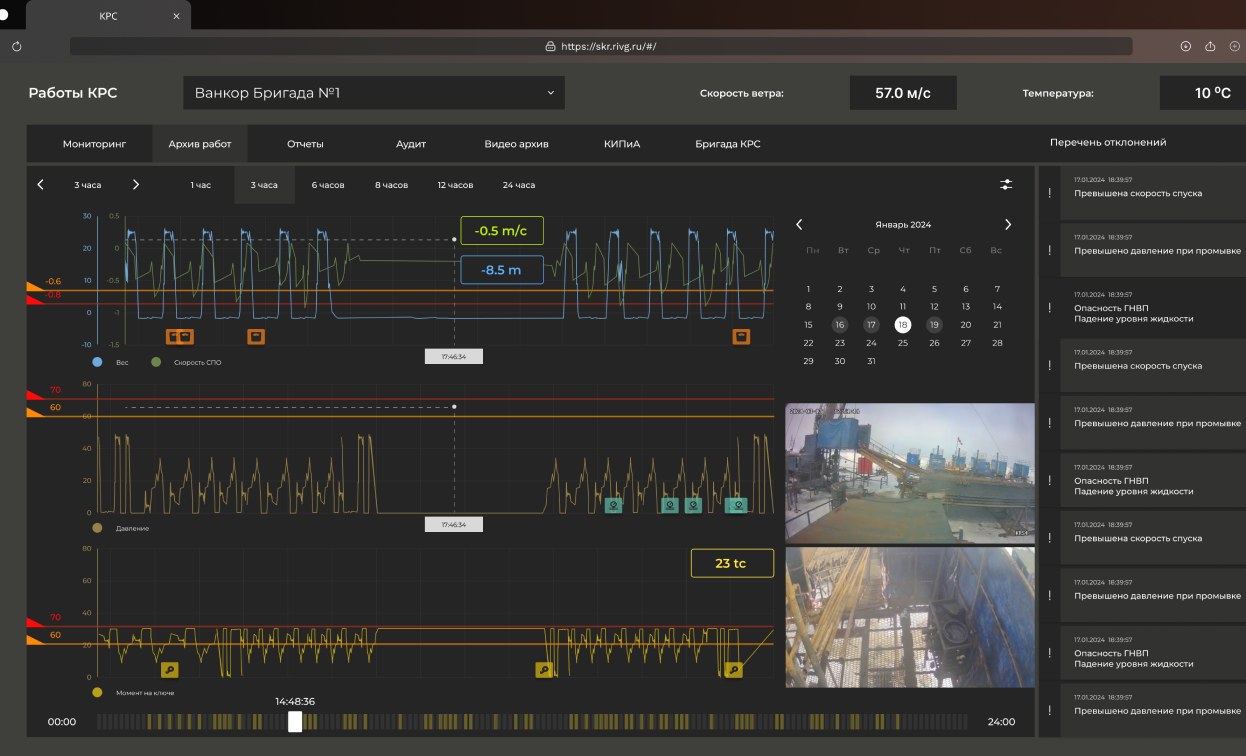

"Single digital window"

For all types of work, including detailed functionality for each direction of oilfield services, registration of data from sensors online. History storage for all works and indicators, automated generation of detailed reporting, monitoring of equipment movement using GLONASS sensors, control of mileage, weight, fuel.

Description

GCF

Scope

Transparency of all production processes

Cattle

Data consolidation in a “single window”

Drilling

Possibility of integrating engineering modules

Automated reporting

AI-based video analytics online

SCADA

Reduction of economic losses due to downtime, defects, incidents, and accidents

Improving management quality and work performance

Effect and value:

The potential effect is achieved by reducing non-productive time, reducing risks, and the ability to manage the technological process in real-time.

Online monitoring of over 100 technological parameters has already been launched at more than 20 facilities, including in extreme northern conditions

Result

Check out other projects:

Learn More

Learn More

SKR Scorpion

A domestic equivalent of an SCADA system for operational support of oilfield works 24/7. Already used in 23 fleets of GCF.

Unified information and analytical system for the preparation, implementation, control, and evaluation of oilfield services.

Unified web portal

Learn More

Learn More

Learn More

Learn More

FaceID ACS

System for automatic authentication of employees by face and granting access to the workplace, including high-risk facilities.

Learn More

Learn More

SCADA for CIC PLC

Mobile information technology complex KIT.KLC. M-03 designed for control and management of the operation mode and supply of liquid chemicals surfactants.

Learn More

Learn More

Inclinometers

Learn More

Learn More

Defectoscope GCF

An automated system for monitoring traffic includes tracking vehicles, dispatching transportation flows, and monitoring.

SCADA – InFlow

Learn More

Learn More

Learn More

Unified system for monitoring, searching, and moving solid waste.

CCTV – InEco

An automated system for managing engineering complexes involves creating a “Digital Twin” of a real infrastructure object.

ACSIS

Подробнее

Learn More

Learn More

Oil and gas industry

Oil and gas industry

Oil and gas industry

Oil and gas industry

Oil and gas industry

Civil construction

Oil and gas industry

Civil construction

Civil construction

Do you have any questions?

Please provide your contact information,

and we will consult you

and we will consult you

Email:

Phone:

Address:

TIN: 9731066109

OGRN: 120770218384

OGRN: 120770218384